End 1980 the first commercial wind project sprang up on the hillsides of Crotched Mountain in Southwest New Hampshire (USA): twenty windmills with a total capacity of 0.6 MW. The interest for wind energy blew over from the United States to Europe and in the nineties the number of windmills increased dramatically. The leading countries were Denmark and Germany, but suddenly a large number of wind turbines also appeared on the horizon in the Netherlands, the UK, Sweden and Spain. Nooteboom keeps a close eye on the world of wind energy through own research.

Wind energy without subsidy – background story

Wind energy is now used worldwide. Interesting emerging markets are Russia, Argentina, Saudi-Arabia and Vietnam. And for the longer term the Philippines, Indonesia, Nigeria and Iran are mentioned as interesting growth markets. In Europe the growth in the coming five years will be much lower than the worldwide figures. Lengthy procedures and stringent regulations restrict the growth in Europe. Everyone wants to back the switch to clean energy, but no one likes to see a windmill in their back yard.

Via political decisions about the levels of subsidies, the government decides the pace at which we can switch to wind energy. The cost of wind energy will in the coming years become lower than electricity generated by fossil fuels. Up to 2022 the growth in Europe will be limited to about 7% per annum. After that the outlook is more favourable and from 2030 onwards at least 50% of all windmills will have to be replaced by new, more efficient ones. If another suitable energy carrier can be found – for instance hydrogen – the windmills will after 2050 disappear again from the densely-populated regions in Western Europe.

The figures

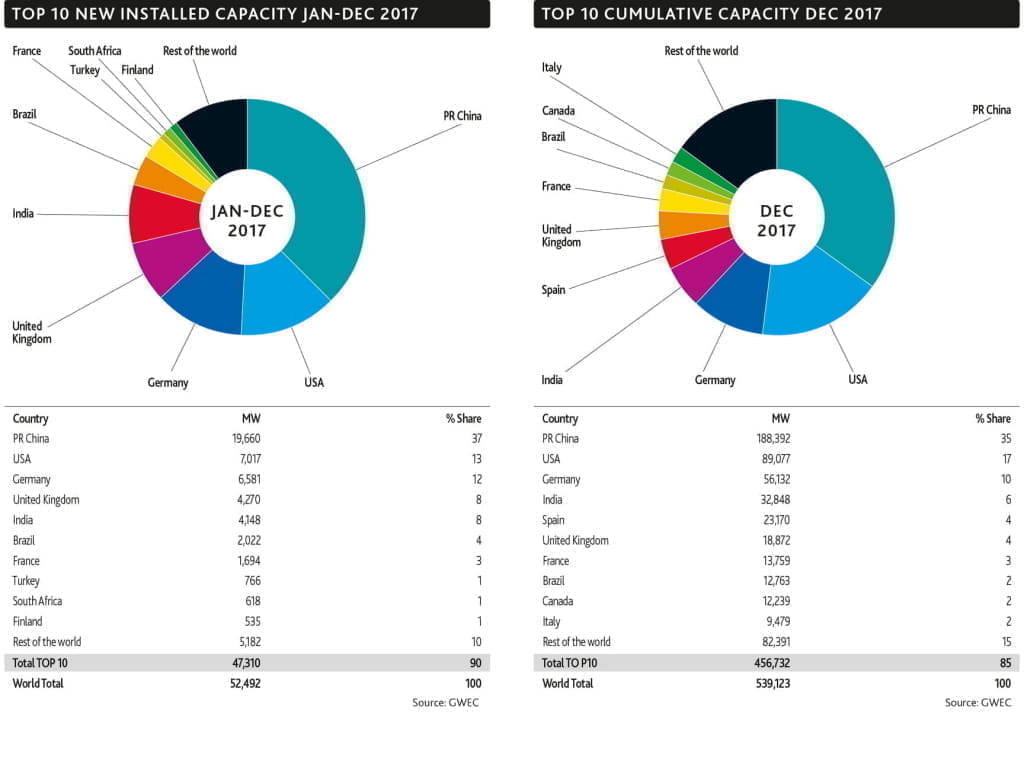

In 2017 wind turbines were installed worldwide with a total capacity of 52,492 MW. This increased the overall capacity to 539,123 MW, a growth of 11%. Of that capacity only 3% are in the sea, but the market for offshore windmills is growing rapidly, especially due to the construction of large wind parks in the North Sea. The most striking development in 2017 is the large reduction in price per kWh. Major tenders for new wind farms in Morocco, Mexico and Canada were offered for a price of approx. US $ 0.03 per kWh. And off the Zeeland coast a wind park will be constructed that can operate without relying on any subsidy. 2017 was a record year in terms of installed capacity in Europe, with Germany and England as frontrunners. The top five worldwide in 2017: China, the USA, Germany, India and Spain.

(Click on the charts to zoom in.)

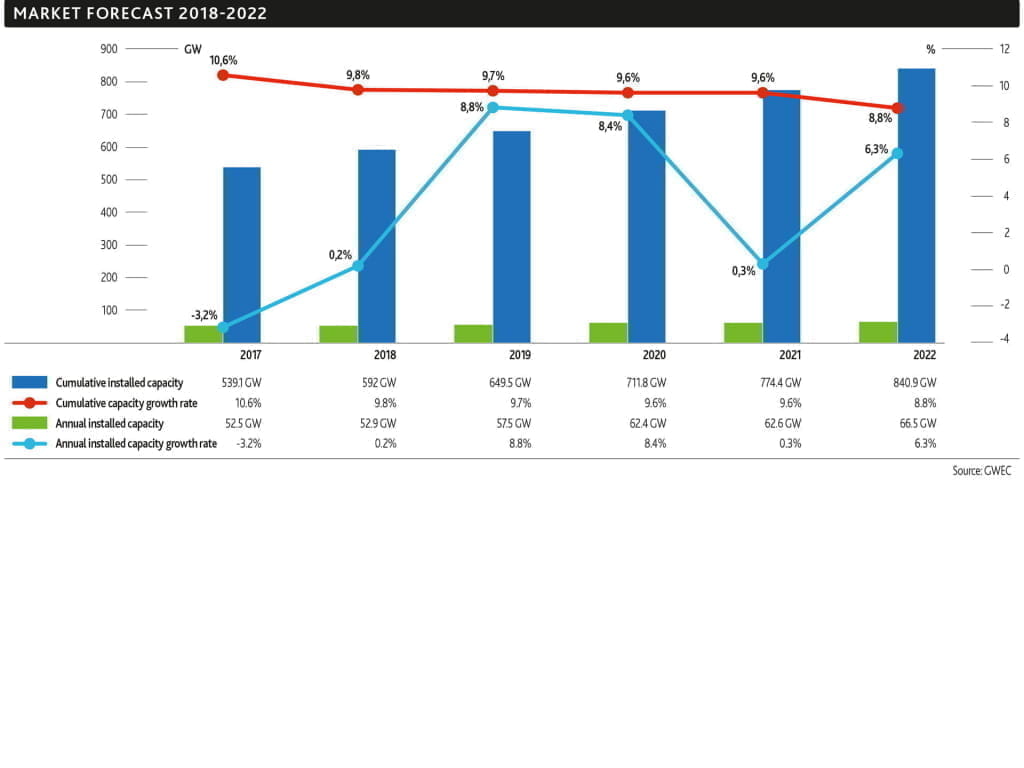

Forecast up to 2022

Up to 2017 generating electricity via wind turbines was more expensive than generating it via conventional coal-fired generation plants. That situation has changed, due to new, vastly improved technology. Wind energy can now compete without a subsidy. As a result of the reduced cost the demand for new windmills worldwide will continue to be high, with a growth percentage of more than 10% per annum. In Europe 2017 was a record year, but for the next few years a lower growth of around 7% is expected. Offshore wind parks around the North Sea account for most of this increase. Their capacity is going to double in the next five years. Within the EU they are working on raising the objective for generating clean energy up to 2030. The new objective for 2030 is 32% clean energy. This could give the construction of windmills in Europe a boost after 2022.

Clean Energy for All Europeans

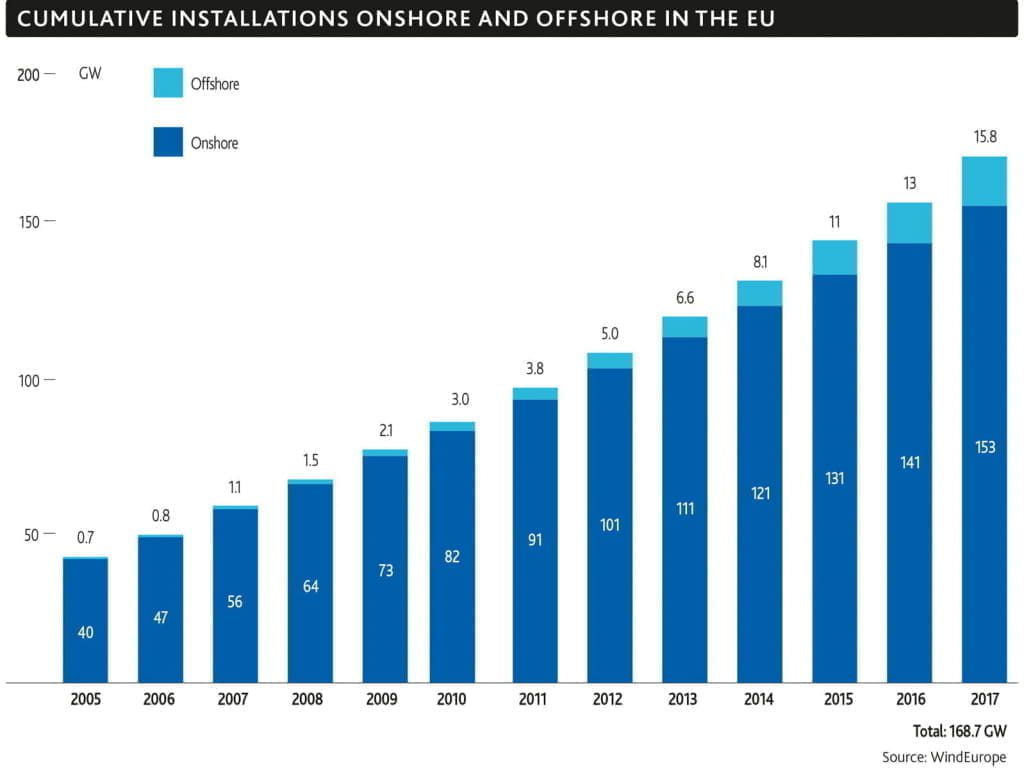

At the end of 2017 a total capacity of 168.7 GW had been installed in Europe, of which 153 GW on land and 15.7 GW offshore. This means the wind parks generated 11.6% of the total energy consumption in the EU. Frontrunners are Denmark (44%) and Portugal (24%). Wind energy provides employment for more than 270,000 people in Europe. For many European countries 2017 was a transitional year. Subsidy schemes will be scaled down in the coming years and growth is restricted by cumbersome and lengthy procedures for the installation of windmills. One of the aims of ‘Clean Energy for All Europeans’ is to streamline and speed up the procedures. The EU will lay down stringent rules regarding the reduction of CO2 emissions and cutting back the use of fossil fuels.

The problems

It’s not only the lengthy procedures that restrict the growth of the number of windmills. Clear-cut solutions have not been found yet either for the storage and transport of the energy generated. ‘Power-management’ systems should improve the coordination between demand and supply. New cables (such as the Cobra cable between the Netherlands and Denmark) will be laid for a better distribution of the generated energy over the European electricity network. For the storage of energy solutions are being sought within Europe and worldwide. One example: in Austria excess energy is stored by pumping water into a lake high in the mountains. The Obervermunt II hydroelectric power station can feed this capacity back to the grid. In Germany there is a pilot project in which a concrete water basin is fitted around the tower of four wind turbines. The storage capacity: 70 MWh, enough for 4,000 electric cars to drive 100 km. The most promising development is the production of hydrogen gas using wind energy. Hydrogen gas can be transported by ship, but the European gas pipeline network could be adapted too. Switching to hydrogen gas as an energy carrier is a huge technical challenge. Furthermore, the cost which currently still is around € 10 per kilogramme must clearly come down. Using hydrogen gas would solve two important problems: storage and transport. Wind energy has to be generated in places where there the wind is strong and where the windmills cause minimum disturbance to the local residents. It is not inconceivable that in 20 or 30 years we will be using hydrogen gas that has been transported by sea from countries around the Pacific. In that case the key areas for the construction of new wind turbines will move to regions a long way from Europe where the wind is strong. Other problems: a rapid transition to the use of electric cars requires major investments in the European electricity network. It is almost certain that in the future the wind and sun will be the source of our energy supply, with the cost of solar energy coming down too. Experts have stated that just part of the Sahara can generate enough solar power for the whole of Europe. In parts of Europe, on a windy day, there is already a surplus of electric energy. The challenge for the coming years is storage, transport and adapting the networks.

The proof is in the price

Up till now the switch to clean energy has been strongly influenced by political decisions. A coal-fired power station supplies power that costs less than € 0.05 per kWh. However on the bill you get at home it says € 0.20 or more. Most of this difference goes to the government in the form of taxes. In recent years the government has given the construction of wind turbines a boost by subsidising them. It is even suggested that windmills are not viable without subsidy. This is only partly true, because the tax revenue from wind energy is lower than the tax revenue from using a polluting coal-fired power station but if you add the costs of the pollution, wind energy is much cheaper. Politics have had a big influence on the development of the wind industry. This influence will disappear, because the sector has grown up and can produce enough cheap energy to compete with the fossil-fuel based energy production. The first tenders with a cost price per kWh of less than € 0.05 are already a reality and the cost of wind energy keeps coming down.

New techniques

The technical developments at the producers of windmills have moved forward significantly over the last few years and there is plenty more to come. An important development is the switch from generators with a gear box to ‘direct-drive’, where the generator turns at the same speed as the rotor blades. The advantages of the direct-drive: fewer moving parts, better cooling, higher output and lower noise production. Divisible generators should make the installation and maintenance simpler. Another development, which will have a big influence on the construction and transport is the ability to produce higher power levels. Until recently no manufacturer managed to cross the 10 MW barrier. GE is the first to introduce a 12 MW offshore wind turbine and reports about a 15 MW version have already appeared in the press. One single windmill of this size will produce power for 12,000 to 15,000 people! The construction of even bigger and taller windmills is now still limited by the size of the components and the capacity of existing crawler cranes. In various places they are working on the development of climbing cranes, which makes it possible to build higher towers. Divisible components, such as rotor blades and generators will make the transport and installation easier.

Weight saving

Wind turbines have become heavier during the last few years. A 7.5 MW version with a concrete/steel tower weighs approx. 6,000 tonnes. 2,500 tonnes are hidden in the foundation, the tower weighs 2,800 tonnes and the generator and rotor blades weigh almost 400 tonnes. Future towers will weigh less. Vestas is working on a prototype that is secured to the ground with cables from halfway up the tower. Modular construction or moving the generator to the bottom of the tower could lead to weight reductions.

The implications for transport companies

Wind energy provides a growing share of our energy needs. But the most important step is still to come: a competitive cost price compared with the power generated from fossil fuels. We are now making that step. In the last decade the cost of wind energy has decreased by more than 50% and it will come down even further. Transport companies and crane hire companies account for part of those lower costs. Transport costs will continue to be under pressure, as only a handful of European windmill producers can choose from the services of several hundreds of transport companies. The transport operator has several options to survive this fierce competition. The first one is to have a higher capacity utilisation for the specialised equipment that is needed for the transport of tower sections, the nacelle or the rotor blades. The second option is to use multifunctional equipment so that the trailer can be used in the wind industry as well as for other transports. The third – perhaps the most important – option is to use multimodal transport more often. Rotor blades up to approx. 70m are still transported over the road. 107m long rotor blades will be coming soon. For the time being these rotor blades are only used for offshore windmills. Long, wide and heavy transports are often easier to transport by water, subject to the height restrictions of the clearance under bridges. A German windmill manufacturer has recently experimented with a dolly underneath a self-supporting rotor blade.

To put the rotor blades at an angle when negotiating tricky parts of the route will also be used more often. ALE has developed a new technology for the transport of very large loads over complicated routes: the Route Survey Tool. This tool provides a detailed electronic analysis of the route beforehand. The separate Driver Assist Tool offers the drivers the opportunity to prepare themselves for the route. In brief: windmills are getting bigger, but their transport has to become cheaper and more efficient.

The trend is higher capacities and longer wings, the longest ones are now 107m long

Nooteboom

Nooteboom began in 1990 as the first trailer producer with the development of special solutions for the transport of windmills.

The Mega Windmill Transporter was a huge success for the transport of tower sections with a large diameter and the Super Wing Carrier is the standard trailer for the transport of ultra-long rotor blades measuring up to 80 metres. For the cranes that are used for the construction of windmills Nooteboom also delivers the most efficient transport solutions, such as the Teletrailer, Ballast trailer and the Manoovr. Nooteboom keeps a close eye on the developments in the wind industry. The Nooteboom policy is to provide – in addition to user friendliness and safety – a lower total-cost-of-ownership (TCO).

The good news

The good news is that the construction of windmills worldwide is advancing well, but at the same time the solutions for the transport and storage of the energy are still in its infancy. If the technology for the production of hydrogen gas improves, the future wind parks will move to thinly-populated regions with strong winds. In a short space of time large wind parks have been built within Europe, but the electricity network has not been adapted yet to distribute the fluctuating production of the wind parks across Europe. Wind energy has become a stable factor in our energy provision, with a cost price that can compete with gas or coal-fired plants. In order to achieve that competitive price all the suppliers that are involved in the construction and transport are required to work even more efficiently. They can count on Nooteboom, because they have been working for years already on extremely efficient solutions for the transport of wind turbines.

Climbing Cranes

Climbing cranes

Wind mills are getting taller all the time and a generator with a weight of over 100 tonnes is no longer the exception. Most windmills are built with conventional cranes. Giant cranes, such as the Liebherr LTM 11200-9.1 mobile crane and the Terex CC 8800-1 crawler crane are used to build the biggest wind turbines. A lot of space is needed to erect these huge cranes and dozens of heavy transport

combinations are required to move the cranes to another building site. On several fronts work is underway to develop crane concepts that need less space and are more efficient to transport. The new cranes must also be able to operate in stronger winds. Various concepts only exist on paper, but two of them are already in use: the Krøll K1650L tower crane is tailor-made for the construction of very tall windmills and to work in higher wind speeds. Dutch company Lagerwey goes one step further with the Climbing Crane. This Climbing Crane was first tested in the autumn of 2017 when they build a Lagerwey L136 wind turbine near the Eemshaven (NL). The complete Climbing Crane is transported on just three vehicles. The development of climbing cranes is still in full swing. Mammoet – the WTA 250 – is working on a version where a guide rail is attached to the tower first. The Climbing Crane of Lagerwey is attached to the tower without a guide rail.

Related products

MEGA WINDMILL TRAILER

The Nooteboom MEGA WINDMILL TRAILER is a unique and universal transport concept, specially designed for the transport of tower sections and nacelles of large windmill installations up to around 3 Megawatt. The MEGA WINDMILL TRAILER adds a new dimension to windmill transportation because of the size, load capacity and manoeuvrability and, more importantly, the reduced operating costs. The MEGA WINDMILL TRAILER is by now used around the world and regarded as the ultimate logistic concept for large tower sections and nacelles. The Nooteboom MEGA WINDMILL TRANSPORTER MEGA Windmill Transporter consists of two hydraulically extendible lift-adapters that can be employed on various vehicle types. During transport the load is clamped between the lift adaptors so that a load floor is not needed. At the front the lift-adapter is usually coupled via a turntable to a 3-axle or 4-axle Nooteboom Jeepdolly. The rear lift adapter is usually coupled via a turntable to a 7-axle hydraulically-steered Nooteboom NLD self-steering dolly.

Read more

SUPER WING CARRIER

The Nooteboom SUPER WING CARRIER is specially designed to transport extremely long windmill rotor blades by road in a handy and efficient way. In order to generate more power the windmills are getting bigger and bigger. And the rotor blades are getting bigger and longer too, measuring up to 70m in length. Conventional extendible semi-trailers are no longer a practical option. The SUPER WING CARRIER is internationally extremely popular for the transport of rotor blades that are 50m long or longer.

Read more

MANOOVR MPL SEMI LOW-LOADER with hydraulic steering and pendle axles

Loads with ever-increasing dimensions and weights, an infrastructure that is getting more congested all the time and different legislation in the various European countries mean that the international specialists in abnormal transport are faced with a challenge that is greater than ever. With the latest generation Nooteboom MANOOVR MPL semi low-loaders the modern transport operator can meet these challenges with ease. The combination of a floor height of 780mm with at least 12 tonnes per axle line anywhere in Europe – including the Netherlands – makes the MANOOVR MPL exceptional.

Read more

OVB TELESTEP

The Nooteboom OVB TELESTEP extendible semi-trailers are specially designed for the transport of ultra-long loads such as rotor blades, tower sections and steel structures. The OVB TELESTEP is equipped with a gooseneck and smaller tyres, which results in a load floor height above the tyres of approx. 1.20m, quite a bit lower than on the flatbed OVB TELETRAILER. Nooteboom has designed the OVB TELESTEP in such a way that even loads up to the maximum permitted fifth wheel weight can be positioned right behind the gooseneck instead of on top of it.

Read more