In the space of one year Nooteboom’s ‘Manoovr’ technology has become a household word in the world of international abnormal transport. The latest innovation in the Manoovr programme is a version with an excavator trough. This option makes the semi low-loader even more versatile, especially for the transport of excavators or demolition machinery as the boom arm can be positioned in the trough.

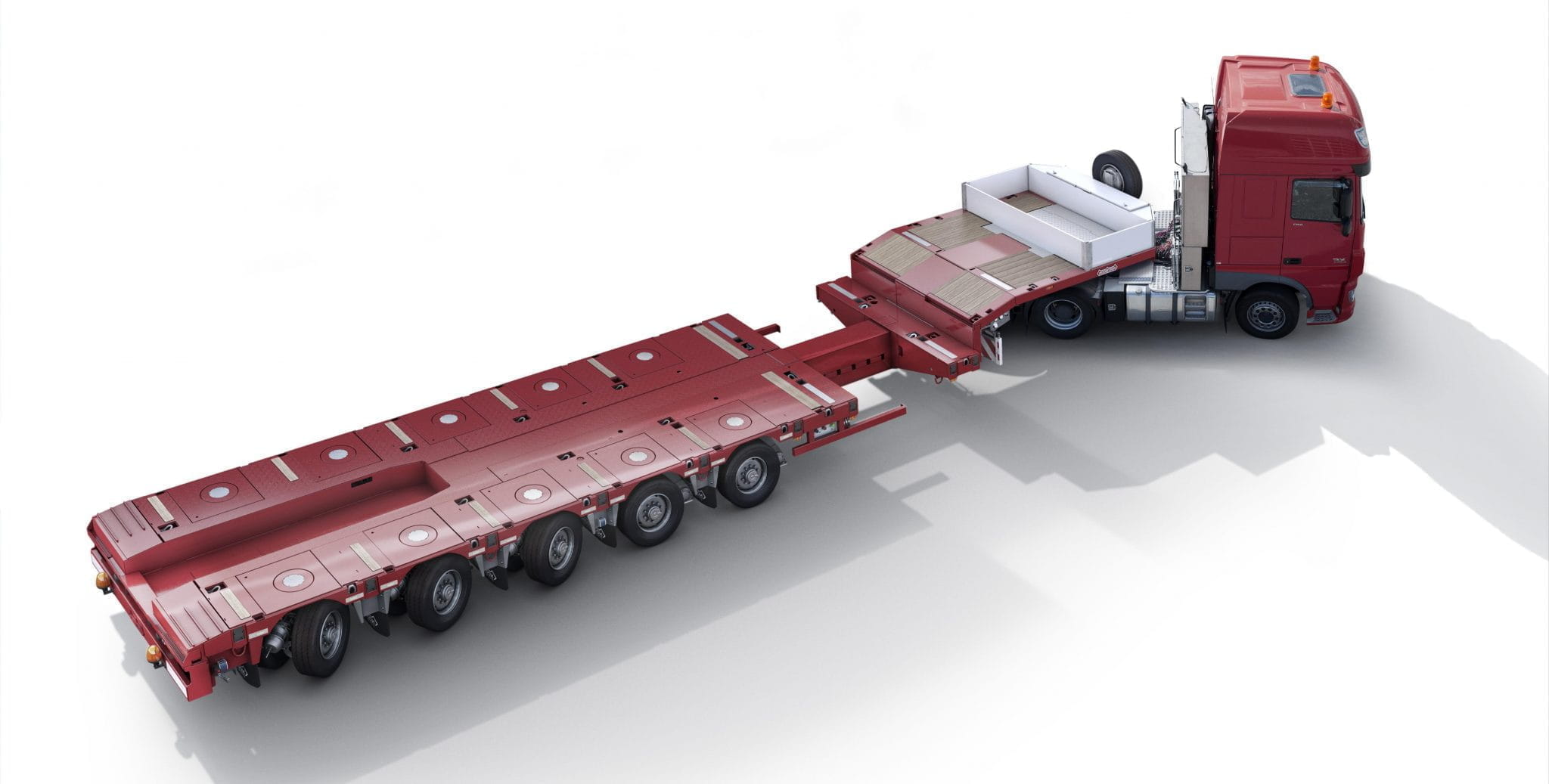

New Manoovr semi lowloader with excavator trough

Expansion Manoovr programme

The excavator trough is available as standard on all semi low-loaders of the Manoovr generation that have up to six axles. Other vehicles from the Manoovr generation can be equipped with an excavator trough on request. The width of the excavator trough depends on the width of the vehicle. With a vehicle width of 2,740 mm the excavator trough is 800 mm wide and with a trailer that is 2,890 mm wide the excavator trough’s width increases to 950 mm. The Manoovr semi low-loader with excavator trough is available with axle distances of 1360 mm or 1510 mm.

The advantages of the Manoovr

With the Manoovr technology Nooteboom offers many advantages that are not affected by the application of an excavator trough. In comparison to alternative brands, the Nooteboom Manoovr semi low-loader has important, unique advantages such as: floor height 780 mm, 500 mm suspension stroke, 60 degrees steering angle, tyres lasting 300,000 km and 12 tonnes per axle in Europe. The result: low tyre costs, low maintenance costs and a high residual value. Combined with aluminium or hydraulic ramps the Manoovr with excavator trough is the ideal multifunctional semi-trailer for the transport of machinery.