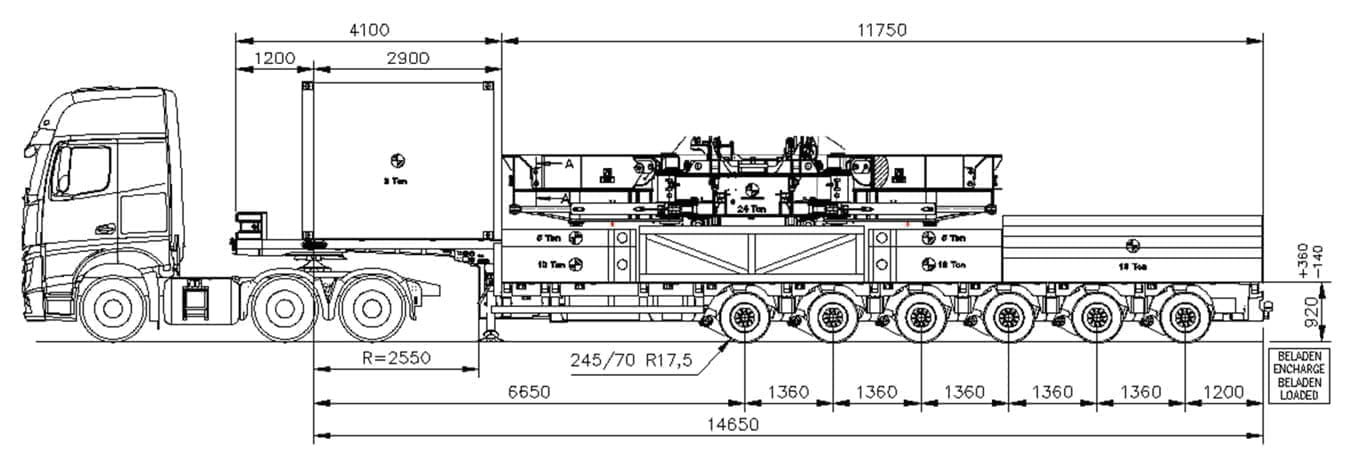

The latest addition to the Ballast trailer programme is the MPL-97-06 with pendle axles. This Manoovr semi low-loader with a fixed 780mm low load floor has 12 tonnes per axle as standard and is therefore internationally an important alternative for the transport of crane ballast within the 100-tonne road network. Load floor height is an increasingly important factor in the crane sector. With a view to safe working at height several crane companies, including Wagenborg Nedlift and Peinemann Kranen, are already using this latest Manoovr Ballast trailer. Depending on the configuration, modern mobile telescopic cranes need up to 9 trailers to carry all the ballast and boom sections.

NEW: Manoovr Ballast trailer

Advantages MANOOVR Ballast trailer:

Compared with the existing flatbed Ballast trailer the Manoovr Ballast trailer offers several extra advantages such as:

- Low load floor of 780 mm, which improves safety when working at height

- 12t axle load

- Manoeuvrability

- Extremely stiff chassis due to an extra high central beam which prevents bending of the floor

- High payload

Peinemann & Wagenborg

The first crane companies that opted for the Manoovr Ballast trailer are Peinemann Kranen from Hoogvliet (NL) and Wagenborg Nedlift from Groningen (NL). Both companies recently took into service this latest Ballast trailer. Peinemann purchased the Ballast trailer specifically to transport the crane components for their LTM1750. Wagenborg Nedlift uses it mainly for their Terex AC500-2. In total Wagenborg Nedlift has purchased three MPL-97-06 for the transport of ballast.

Ballast trailer programme

The latest addition to the Ballast trailer programme is the MPL-97-06 semi low-loader with fixed load floor. This Ballast trailer is based on Manoovr technology and has pendle axles which, with a 12-tonne axle load, provide an extremely high payload.

The programme also includes the flatbed Ballast trailer, available with up to 7 axles and equipped with the unique countersteering system.

History Nooteboom Ballast trailer

Back to 1953

Many European crane companies use Nooteboom Ballast trailers for the efficient transport of ballast and boom sections. In order to understand the close relationship between Nooteboom and the crane hire companies we must go back to 1953. In that year Anton Nooteboom built a hydraulic crane on a Ford V8 chassis. Lifting and luffing were both done via hydraulic cylinders. The concept of this hydraulic mobile crane was extremely advanced. In the fifties Nooteboom gradually produced more products for road transport, initially tippers for carrying sand, followed by heavy semi-trailers. This experience with the hydraulic systems of cranes fitted in seamlessly with the development of tippers and steered semi-trailers. Around 1960 the demand for heavy low-loaders increased rapidly and Nooteboom decided to fully concentrate on abnormal road transport. The crane production was sold in 1963, but the good relationship with the crane hire companies continued to exist.

The first Ballast trailer

In 1984 the largest telescopic crane in the fleet of Van Seumeren was a Liebherr LT1200, an imposing 200-tonne crane. In those days the lifting capacity increased year by year and when the LT1300 – a 300-tonne crane – came on the market, Jan van Seumeren Sr. traded in his LT 1200. With the higher lifting capacity the ballast weight also rose from 40 to 60 tonnes. After extensive consultations between Jan van Seumeren Sr., Dick Nooteboom and the RDW (Dutch Road Administration) the first Ballast trailer was developed: the OBL-78 with a load capacity of 68 tonnes. The 6-axle ballast trailer, pulled by a DAF 8×4 tractor, had important advantages: an impressive load capacity and a permanent exemption so the DAF-Nooteboom combination was permitted to drive on the national roads. However, the biggest advance was that the exemption was granted for a divisible load. This in contrast to regular abnormal transport, where exemptions for heavy weights are usually only granted for indivisible loads.

In 1953-1963 Nooteboom already built hydraulic telescopic cranes up to 33 meters and, in doing so, were way ahead of their time

The first Ballast trailer (van Seumeren)

Not just in the Netherlands

Based on the positive experiences in the Netherlands the ballast trailer was, after some very strong lobbying by Nooteboom and their customers, approved in other European countries too. Belgium, Germany and Great-Britain followed the Dutch example first and in 2004, after years of negotiations, the ballast trailer concept was approved in France too. But the ballast trailer has also found the way to countries such as Denmark, Italy, Poland, Austria, Spain and Switzerland. However, the permitted legal loads are different in every country and that’s why various versions of the ballast trailer have been developed, ranging from four to seven axles. With their current programme of ballast trailers Nooteboom has a solution for every country, adapted to meet the regulations that apply.